Hổ trợ trực tuyến

|

|

|

0902937088 0902937088

|

|

Ms Liên: lien.ans@ansvietnam.com |

|

Menu sản phẩm

Ứng dụng

Hãng sản xuất

Lượt truy cập

|

Đang online | 292 |

|

Lượt truy cập | 8722916 |

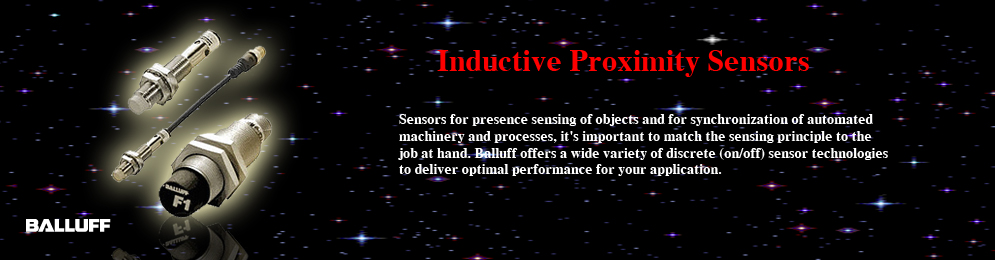

Kason self-contained system with circular fluid bed processor

Loại sản phẩm: Motor & pump

Mã sản phẩm: Kason self-contained system with circular fluid bed processor

Nhà cung cấp: ANS Vietnam

Xuất Xứ: Chính hãng

Hãng sản xuất: Tomoe

Giá : Vui lòng liên hệ

Fluid Bed Dryers, Coolers, and Moisturizers for bulk foods, pharmaceuticals, and chemicals

Description

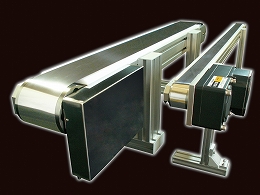

Because the circular fluid bed processor is also more compact, complete fluid bed systems can be pre-engineered and pre-configured on caster-mounted frames, ready for installation and start up.

Moreover, Kason circular fluid bed processors maintain an unprecedented level of operating efficiency across a wide range of model size from 18 to 84 inches (450 to 2125 mm) in diameter for laboratory and pilot plant testing as well as batch or high-volume in-line drying, cooling, or moisturizing of bulk foods, pharmaceuticals, and chemicals.

Features

- Inherently rigid, a Kason circular fluid bed processor does not require heavy steel sidewalls or cross braces to withstand extensive vibration.

- A Kason circular fluid bed processor uses a lighter gauge shell and components, with fewer weld seams, and requires only one air inlet and outlet resulting in lower material and labor costs.

- This self-contained fluid bed systems are lab tested using your material, engineered, and configured on a frame to ensure on-spec performance as delivered.

- Compact and lightweight, a complete Kason circular fluid bed system can be frame-mounted with casters for low cost shipping, easy installation, and in-plant mobility.

- With no internal cross members, fewer seams and corners, and a quick disconnect shell, a Kason circular fluid bed processor cut cleaning time dramatically.

Principle of Operation

Continuous air flow and vibration separate and fluidize individual particles, maximizing the surface area of material and, accordingly, the rate at which drying, moisturizing, heating, or cooling can occur.

To prevent the uppermost layers of fluid bed particles from being pulled into the exhaust stream, the fluid bed exhaust plenum tapers outward to a longer diameter than that of the fluid bed screen surface, effectively reducing the air velocity by 50 percent.

The vibratory motion of the processor also serves to convey the material along a defined pathway for uniform processing on a "first in/first out" basis, and to evacuate the fluid bed at the end of each cycle.

To fit your material application and integrate with existing plant equipment, TOMOE offers a comprehensive range of equipment available as components, sub-systems, or complete systems as described below.

Sản phẩm liên quan

Pyles

Plastic surface treater

Lensed fiber (Nanonics)

NSOM optical fiber probe

NanoAnalytics Q-Control S ...

NSOM/AFM confocal microsc ...

ZIRCAR alumina fibers

ZIRCAR Zirconia fibers

Molded Quarz

Apply Ceramic to Worn Par ...

Manual wire bonder

Pin Mat

Tac Sheet (Gel adhesive s ...

Capillary

Hub blade

Steel Belt for Oil Skimme ...

Steel Belt Conveyor

Stainless Steel Belt

PBN

PG/PBN Heater

Pyrolytic Graphite

Alumina powder

BN ( Boron nitride )

Sintec Ceramic Powder and ...

IMC Aluminum Evoporator B ...

SiC Powder

UV curing resins

Phenoxy resins

Alumina Hydrate

K-Seal and Kuniseal

Silica fume

Wollastonite

Cenolite ( ceramic balloo ...

Vermiculite

Sepiolite Attapulgite

ECO-3

Rustec VCI Film

Moisture sealing sheet

Abrasive Grain Recycle Sy ...

Waste Plastic Separation ...

Paper,Pulp,Electric Power

Rotary Press Filter

Kason self-contained syst ...

ASM Tubular Centrifuge

FMD Decanter

Food & Pharmaceutical

Kason self-contained syst ...

PTM Decanter ( Screen Bow ...

TRH Decanter

Chemical & Petrochemical

In-Channel Grinder, Scree ...

In-Line Grinder

Rotary Press Filter

BDF Decanter

TSM Decanter